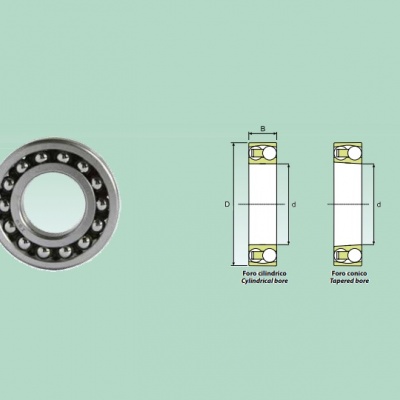

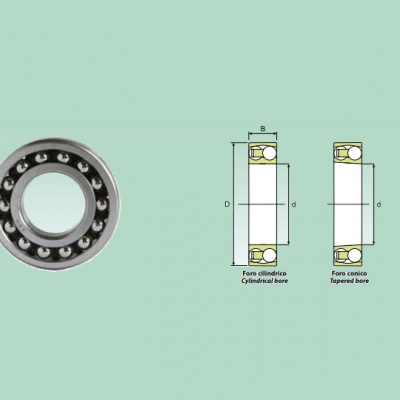

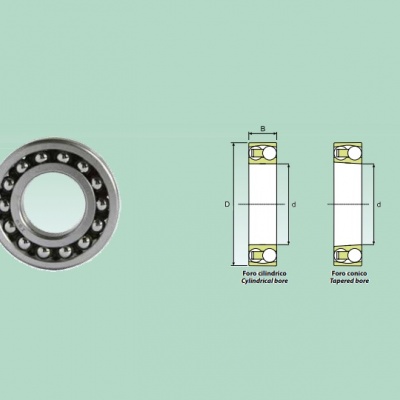

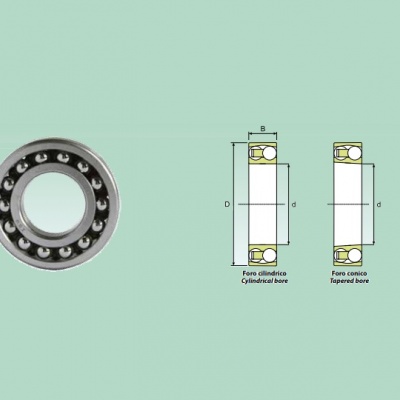

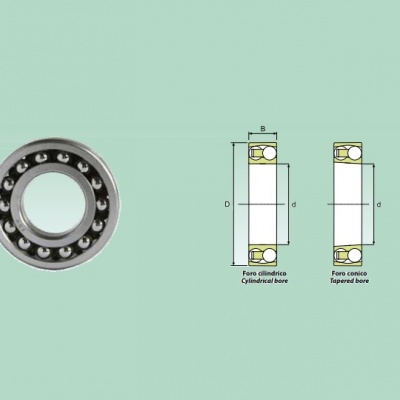

ISB self-aligning ball bearings have two rows of balls and just one spherical raceway on the outer ring. This type of design means that the bearing is self-aligning and is not subjected to any misalignment problems.

It is designed to be used in applications where there could be misalignment errors or considerable shaft deflections. It is particularly suitable for working at high speeds because, out of the wide range of rolling bearings, ISB® self-aligning ball bearings are those with lowest friction.

These types of bearings are supplied in three different versions:

• Basic design open bearings;

• Sealed bearings;

• Open bearings with wider inner ring,

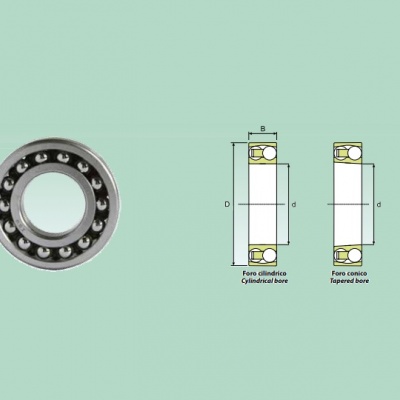

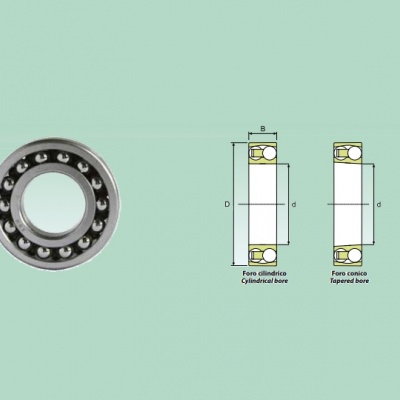

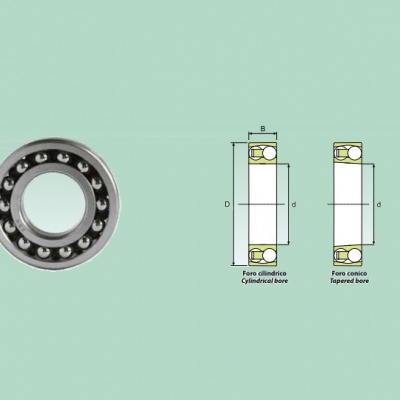

Basic design version

Available with cylindrical bore or tapered bore in certain dimensional ranges (taper 1:12).

These bearings have annular groove and lubrication holes on the inner ring and also on the outer ring. Sealed bearings

This is the sealed variant lubricated with grease and with efficient rust-inhibiting capacity, This type of lubrication is guaranteed for life and means that the bearing is maintenancefree.

The seals are made of Nitrile-Butadiene-Rubber (NBR), which is resistant to oil and wear and are reinforced with sheet steel, The operational temperature range is -40°C to +100°C, and up to +120°C just for short periods, The seal lip applies a slight pressure on a special smooth groove on the inner ring.

Likewise for the basic design version, these bearings have a cylindrical bore and a tapered bore (taper 1:12). Before mounting, the sealed bearings should not be washed or heated to temperatures above +80°C; the designation suffix is 2RS, Bearings with wider inner ring They are specific drawn bearings for shafts; the ease of assembly and disassembly are guaranteed by the special tolerances of the bore.

They are fitted axially on the shaft thanks to a pin or screw, which in turn fits in the recess on one side of the ring so that the latter does not turn on the shaft.

Bearings with sleeve

Bearings with tapered bore are fitted on a cylindrical shaft by means of adapter and withdrawal sleeves. These facilitate assembly and disassembly. The withdrawal sleeves require an axial locking device on the shaft, whereas the adapter sleeves to not, consequently the latter are more popular.

Dimensions

The overall dimensions of ISB® self-aligning ball bearings comply with standard ISO 15:1998.

Tolerances

ISB® self-aligning ball bearings are usually manufactured with Normal tolerances pursuant to ISO 492:2002, The versions with wider inner ring are an exception and their bore belongs to tolerance class JS7.

Misalignment

Misalignments could occur between the inner ring and the outer ring, but they do not have a detrimental effect on performance thanks to their constructional design, which characterises such bearings.

Internal clearance

Together with the Normal internal radial clearance, many versions of ISB self-aligning ball bearings are available with smaller clearance (C2), greater clearance (C3) or much greater clearance (C4).

Cages

ISB self-aligning ball bearings, based on the size and series, are supplied with the following cages:

• Single-piece pressed sheet steel cage.

• Two-piece sheet steel cage.

• Injection moulded cage made of polyamide 6,6 with fibreglass reinforcement, centred on the balls, with suffix TN9.

• Solid machined brass cage.

Axial load carrying capacity

When ISB self-aligning ball bearings with adapter sleeve are fitted on drawn shafts without shoulders, the capacity to withstand axial loads depends on the friction between sleeve and shaft.

Supplementary designations

C3 Internal radial clearance greater than Normal,

K Tapered bore, taper 1:12

M Solid machined brass cage, centred on the balls

2RS Nitrile-Butadiene-Rubber (NBR) contact seals with sheet steel reinforcement, on both sides of the bearing

TN9 Injection moulded snap-type cage made of polyamide 6,6 with fibreglass reinforcement, centred on the balls.

It is designed to be used in applications where there could be misalignment errors or considerable shaft deflections. It is particularly suitable for working at high speeds because, out of the wide range of rolling bearings, ISB® self-aligning ball bearings are those with lowest friction.

These types of bearings are supplied in three different versions:

• Basic design open bearings;

• Sealed bearings;

• Open bearings with wider inner ring,

Basic design version

Available with cylindrical bore or tapered bore in certain dimensional ranges (taper 1:12).

These bearings have annular groove and lubrication holes on the inner ring and also on the outer ring. Sealed bearings

This is the sealed variant lubricated with grease and with efficient rust-inhibiting capacity, This type of lubrication is guaranteed for life and means that the bearing is maintenancefree.

The seals are made of Nitrile-Butadiene-Rubber (NBR), which is resistant to oil and wear and are reinforced with sheet steel, The operational temperature range is -40°C to +100°C, and up to +120°C just for short periods, The seal lip applies a slight pressure on a special smooth groove on the inner ring.

Likewise for the basic design version, these bearings have a cylindrical bore and a tapered bore (taper 1:12). Before mounting, the sealed bearings should not be washed or heated to temperatures above +80°C; the designation suffix is 2RS, Bearings with wider inner ring They are specific drawn bearings for shafts; the ease of assembly and disassembly are guaranteed by the special tolerances of the bore.

They are fitted axially on the shaft thanks to a pin or screw, which in turn fits in the recess on one side of the ring so that the latter does not turn on the shaft.

Bearings with sleeve

Bearings with tapered bore are fitted on a cylindrical shaft by means of adapter and withdrawal sleeves. These facilitate assembly and disassembly. The withdrawal sleeves require an axial locking device on the shaft, whereas the adapter sleeves to not, consequently the latter are more popular.

Dimensions

The overall dimensions of ISB® self-aligning ball bearings comply with standard ISO 15:1998.

Tolerances

ISB® self-aligning ball bearings are usually manufactured with Normal tolerances pursuant to ISO 492:2002, The versions with wider inner ring are an exception and their bore belongs to tolerance class JS7.

Misalignment

Misalignments could occur between the inner ring and the outer ring, but they do not have a detrimental effect on performance thanks to their constructional design, which characterises such bearings.

Internal clearance

Together with the Normal internal radial clearance, many versions of ISB self-aligning ball bearings are available with smaller clearance (C2), greater clearance (C3) or much greater clearance (C4).

Cages

ISB self-aligning ball bearings, based on the size and series, are supplied with the following cages:

• Single-piece pressed sheet steel cage.

• Two-piece sheet steel cage.

• Injection moulded cage made of polyamide 6,6 with fibreglass reinforcement, centred on the balls, with suffix TN9.

• Solid machined brass cage.

Axial load carrying capacity

When ISB self-aligning ball bearings with adapter sleeve are fitted on drawn shafts without shoulders, the capacity to withstand axial loads depends on the friction between sleeve and shaft.

Supplementary designations

C3 Internal radial clearance greater than Normal,

K Tapered bore, taper 1:12

M Solid machined brass cage, centred on the balls

2RS Nitrile-Butadiene-Rubber (NBR) contact seals with sheet steel reinforcement, on both sides of the bearing

TN9 Injection moulded snap-type cage made of polyamide 6,6 with fibreglass reinforcement, centred on the balls.