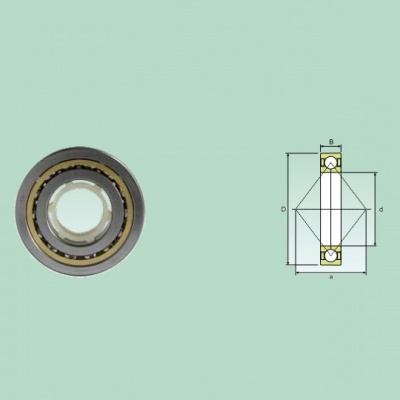

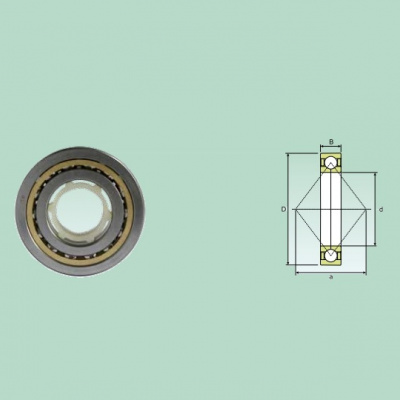

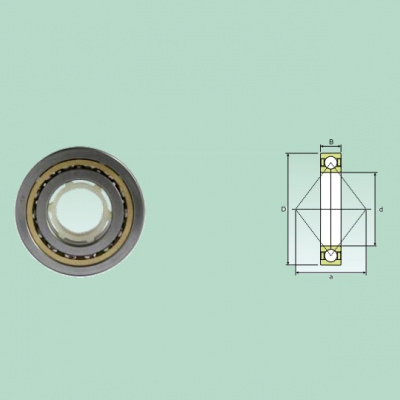

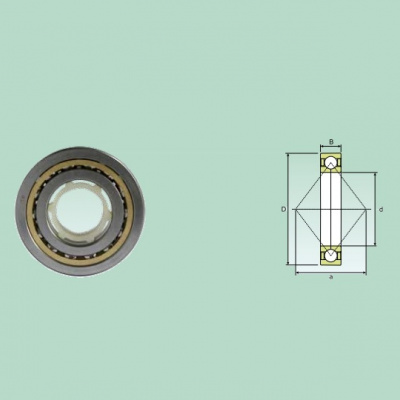

ISB four-point contact bearings are single row angular contact ball bearings with raceways designed to withstand axial loads from both directions; they occupy much less axial space compared to ISB double row angular contact ball bearings. They are supplied in two ranges, QJ2 and QJ3 in the following versions:

• Standard

• With locating slots

Standard bearings

They are designed to withstand axial loads and their contact angle is 35°. The ring can be separated into two halves so that the bearing can incorporate a large number of balls, which ensures a high load carrying capacity. ISB four-point contact ball bearings are separable

Bearings with locating slots

There are many applications in which one single row deep groove radial bearing is combined with a four-point contact ball bearing so that the outer ring does not turn circularly. For this reason, bearings with suffix N2 have two slots in the outer ring, positioned at 180° one compared to the other (Fig. 2).

Dimensions

The overall dimensions of ISB four-point contact ball bearings comply with standard ISO 15:1998. Tolerances ISB four-point contact ball bearings are manufactured pursuant to the Normal tolerance class. Following the specifications of tolerance class P6, some sizes are also available with higher precision ratings.

Internal clearance

ISB four-point contact ball bearings are manufactured standard with Normal internal axial clearance. Misalignment The misalignment tolerance capacity between inner ring and outer ring is limited, consequently the ability to compensate any misalignments and tolerance compared to the shaft deflections is limited.

Cages

The only cage available for this type of bearing is the solid machined window-type brass cage, centred on the outer ring.

Supplementary designations C2 Internal axial clearance smaller than Normal C3 Internal axial clearance greater than Normal C4 Internal axial clearance greater than class C3 M Solid machined window-type brass cage, centred on the outer ring N2 Two locating slots on the wide side face of the outer ring, at 180° one compared to the other P6 Dimensional and rotation precision according to tolerance class 6 of ISO standard

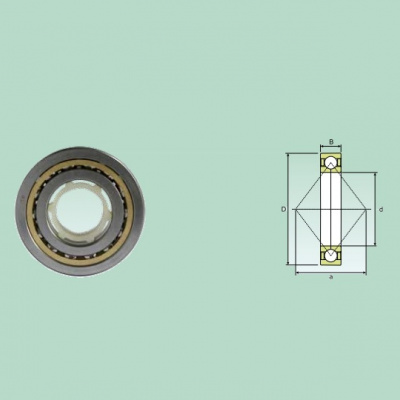

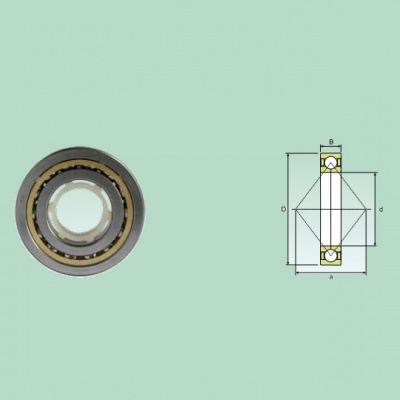

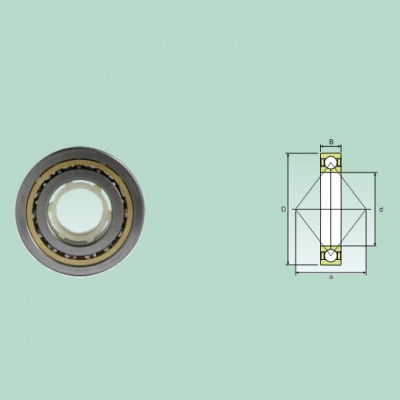

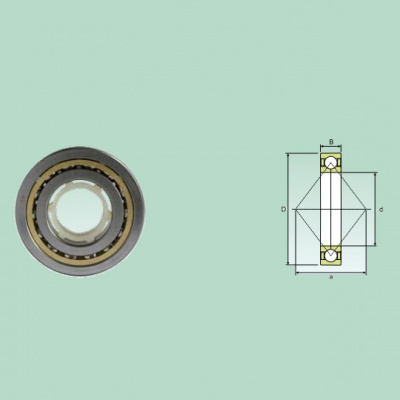

• Standard

• With locating slots

Standard bearings

They are designed to withstand axial loads and their contact angle is 35°. The ring can be separated into two halves so that the bearing can incorporate a large number of balls, which ensures a high load carrying capacity. ISB four-point contact ball bearings are separable

Bearings with locating slots

There are many applications in which one single row deep groove radial bearing is combined with a four-point contact ball bearing so that the outer ring does not turn circularly. For this reason, bearings with suffix N2 have two slots in the outer ring, positioned at 180° one compared to the other (Fig. 2).

Dimensions

The overall dimensions of ISB four-point contact ball bearings comply with standard ISO 15:1998. Tolerances ISB four-point contact ball bearings are manufactured pursuant to the Normal tolerance class. Following the specifications of tolerance class P6, some sizes are also available with higher precision ratings.

Internal clearance

ISB four-point contact ball bearings are manufactured standard with Normal internal axial clearance. Misalignment The misalignment tolerance capacity between inner ring and outer ring is limited, consequently the ability to compensate any misalignments and tolerance compared to the shaft deflections is limited.

Cages

The only cage available for this type of bearing is the solid machined window-type brass cage, centred on the outer ring.

Supplementary designations C2 Internal axial clearance smaller than Normal C3 Internal axial clearance greater than Normal C4 Internal axial clearance greater than class C3 M Solid machined window-type brass cage, centred on the outer ring N2 Two locating slots on the wide side face of the outer ring, at 180° one compared to the other P6 Dimensional and rotation precision according to tolerance class 6 of ISO standard